Sodium Hydrosulfite - Sodium Dithionite

Available, delivery time: 1-3 days

Without Sodium Hydrosulfite / Sodium Dithionite no indigo dyeing or colour stripping

Sodium Dithionite (a.k.a. Sodium Hydrosulfite) is used for indigo dyeing and also for colour stripping of fabrics.

This chemical is needed as a reducing agent in indigo dyeing. Sodium Dithionite is also contained in every commercially available fabric colour stripper (but in a very low dosage).

Sodium Dithionite (Sodium Hydrosulfite) for indigo and dyer's woad

To reduce the indigo dye you also need, in addition to soda, Sodium Dithionite / Sodium Hydrosulfite. This produces the famous indigo vat.

For dyeing with powdered (pre-reduced) indigo you need Sodium Dithionite as reactive agent. It is added during the dyeing process.

It is also used to revive the dye liquor.

You also need this chemical for dyeing with dyer's woad.

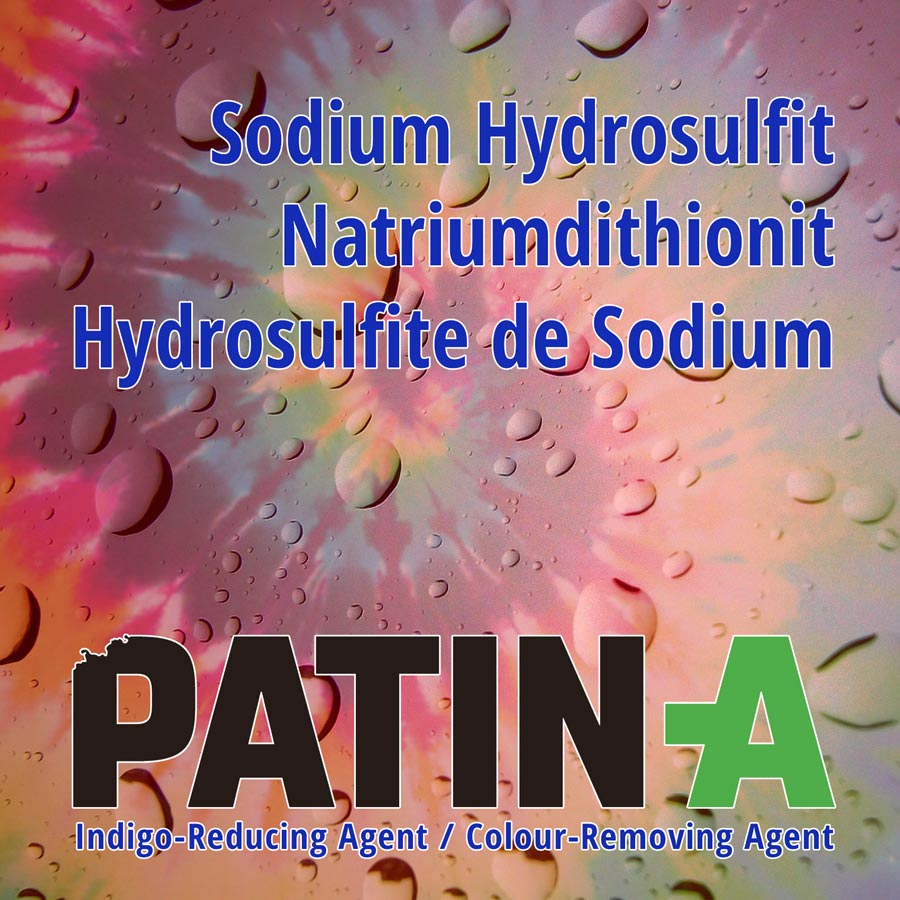

1 part of pre-reduced indigo dye & 2 parts of sodium hydrosulfite & 4 parts of soda (use 4 liters of water per 20g of dye).

Discolour fabrics with Sodium Dithionite / Sodium Hydrosulfite

To remove colours from fabrics, add equal parts of Sodium Hydrosulfite with Soda (Sodium Carbonate) (1:1) on 3-5% of the dry weight of the fabric.

Meaning: 3 - 5 gram per 100 gram of fabric weight.

Heat the liquid to 85°C, add the fabric and continue heating. Colour stripping works best with boiling liquid.

Keep the fabric in motion for 10 to 20 minutes or until the colour has come out as desired. Then wash with mild detergent in cold water.

Please note: not all dyes can be removed from fabrics. Results may vary. If possible, make a test first.

Interesting facts about sodium dithionite / sodium hydrosulfite

The property that dithionites decompose relatively easily makes them suitable as bleaching or reducing agents.

When dyeing with indigo, the blue indigo is converted into white indigo with the help of sodium dithionite (sodium hydrosulfite) during the vatting process (indigo = vat dye), which forms a water soluble salt with the added sodium hydroxide solution.

After having been dipped into the vat, the textiles turn yellow through the indigo white. As soon as you take the textiles out of the vat, the vat dye oxidises to blue indigo - you get the typical, jeans blue colour.

Sodium dithionite is also used to bleach sugar, syrup, wood-containing paper and wood pulp, but also to separate silver from fixing baths.

Compostable packaging:

The packaging is compostable and made from renewable raw materials.

Of course, the resealable pressure seal bag is free from petroleum based plastics.

A small contribution to environmental protection.

Content: 250g oder 500g

Selling unit: 1 pack (250g oder 500g)

Danger warnings:

Use product with care. Always read the label and warnings before use.

• Sodium Hydrosulfite is harmful when swallowed. If swallowed, give water or milk and call a doctor.

• Causes severe eye irritation. Wear eye protection. If medical advice is needed, have packaging or label ready.

• Capable of self heating; can catch fire.

• Keep out of the reach of children.

• Read label before use.

• Avoid release to the environment.

• Dispose of content/container according to local regulations.

Discolour fabrics with Sodium Dithionite / Sodium Hydrosulfite

Decolourising powder (sodium dithionite):

3 - 5 grams per 100 grams fabric weight.

1kg fabric weight requires 30 - 50 grams of powder.

Amount of water:

As much water as needed to cover the garments with water.

Water temperature:

Initially 85ºC heat to 95ºC

• To remove colours from fabrics, add equal parts of Sodium Hydrosulfite with Soda (Sodium Carbonate) (1:1) on 3-5% of the dry weight of the fabric.

• Heat the liquid to 85°C, add the fabric and continue heating. Colour stripping works best with boiling liquid.

• Keep the fabric in motion for 10 to 20 minutes or until the colour has come out as desired. Then wash with mild detergent in cold water.

• Please note: not all dyes can be removed from fabrics. Results may vary. If possible, make a test first.

Sodium Dithionite (Sodium Hydrosulfite) for indigo and dyer's woad

2 parts of sodium hydrosulfite & 1 part of pre-reduced indigo dye & 4 parts of soda

(Use 4 liters of water per 20g of dye)

• To reduce the indigo dye you also need, in addition to soda, Sodium Dithionite / Sodium Hydrosulfite. This produces the famous indigo vat.

• For dyeing with powdered (pre-reduced) indigo you need Sodium Dithionite as reactive agent. It is added during the dyeing process.

• Sodium Dithionite is also used to revive the dye liquor.

• You also need this chemical for dyeing with dyer's woad.

You can find detailed instructions on how to dye indigo in the product description of indigo textile dye at www.patin-a.de.

Danger warnings:

Use product with care. Always read the label and warnings before use.

|

|

• Sodium Hydrosulfite is harmful when swallowed. If swallowed, give water or milk and call a doctor.

• Causes severe eye irritation. Wear eye protection. If medical advice is needed, have packaging or label ready.

• Capable of self heating; can catch fire.

• Keep out of the reach of children.

• Read label before use.

• Avoid release to the environment.

• Dispose of content/container according to local regulations.

250g = 1,74€

500g = 3,48€

Verpackung: 0,4

Labels: 0,1

0 of 0 reviews

Login

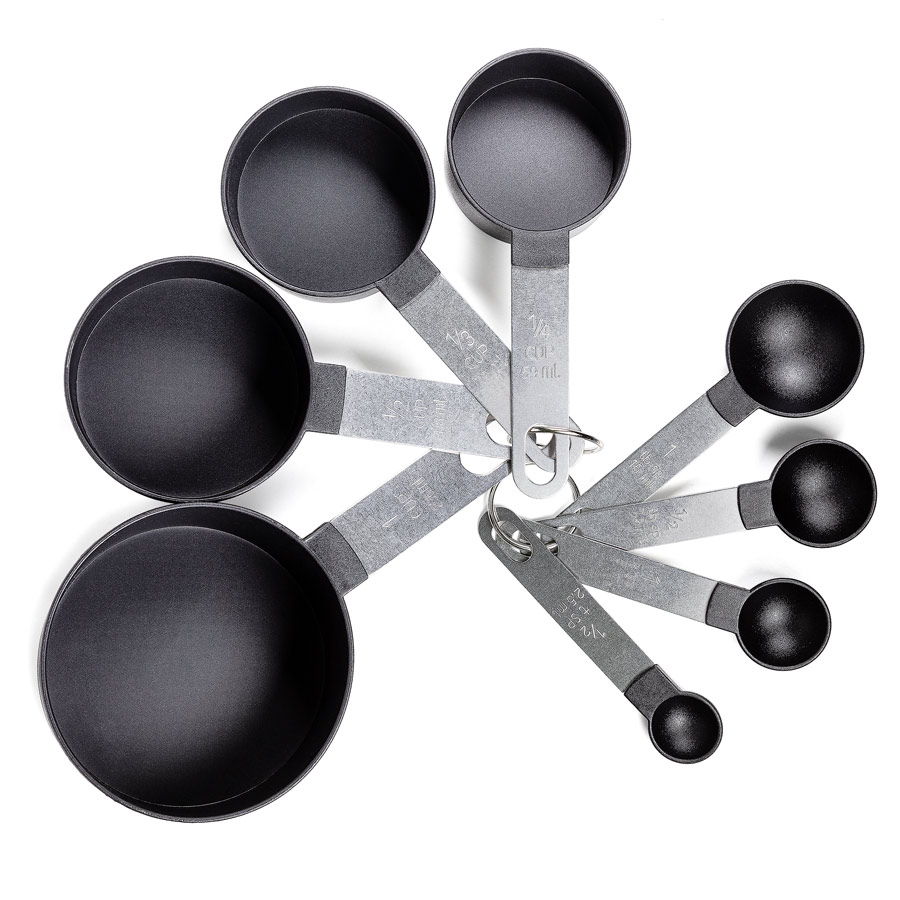

Accessories

Content: 0.014 Kilogram (€710.71* / 1 Kilogram)

Content: 0.8 Kilogram (€32.44* / 1 Kilogram)

Content: 0.6 Kilogram (€16.58* / 1 Kilogram)

Similar Products

Content: 0.023 Kilogram (€302.17* / 1 Kilogram)

Content: 0.45 Kilogram (€15.44* / 1 Kilogram)

Customer Also Viewed

Content: 0.227 Kilogram (€250.88* / 1 Kilogram)

Content: 4 Piece (€3.24* / 1 Piece)

Customer Also Bought

Content: 0.014 Kilogram (€389.29* / 1 Kilogram)

Content: 14 Gram (€0.57* / 1 Gram)

Content: 0.5 Kilogram (€3.70* / 1 Kilogram)

Content: 0.014 Kilogram (€389.29* / 1 Kilogram)

Content: 14 Gram (€0.57* / 1 Gram)

Content: 0.5 Kilogram (€129.90* / 1 Kilogram)

Content: 10 Gram (€0.32* / 1 Gram)

Content: 0.5 Kilogram (€149.90* / 1 Kilogram)

We ship worldwide

We ship worldwide Top customer satisfaction!

Top customer satisfaction! Many payment options

Many payment options